Face Mask Material

Currently designed as general population face mask media

- Multi layer composite material - no lamination needed

- Filtration core of unique meltblown technology

| BFE | PFE | Air Flow1 | Air Perm** | Breathability* | |

|---|---|---|---|---|---|

| France Public | N/A | >70% | N/A | >96 | N/A |

| France Professional | N/A | >90% | N/A | N/A | <70 |

| Belgium Public | >70% | N/A | N/A | N/A | <70 |

| Portugal Public | >70% | N/A | >8 | N/A | N/A |

| SYNERGEX™ ONE | >85% | >90% | 70 | 160 | 50 |

| *Air Flow is measured by = Pressure flow under 40 Pa - test head 20 cm2 > 8 l/min ** Air permeability is measured by = Pressure drop @ 100 Pa (l/m2/s) >96 x Breathability is measured by = Differential pressure according to EN EN14683 and is measured in P/cm2 |

|||||

It is the customer's sole responsibility to verify the properties of the finished product manufactured with Synergex ONE and ensure conformity for any regulatory requirements including the Standard (EN) 14683.

Performance Summary

Investing to continue performance improvement

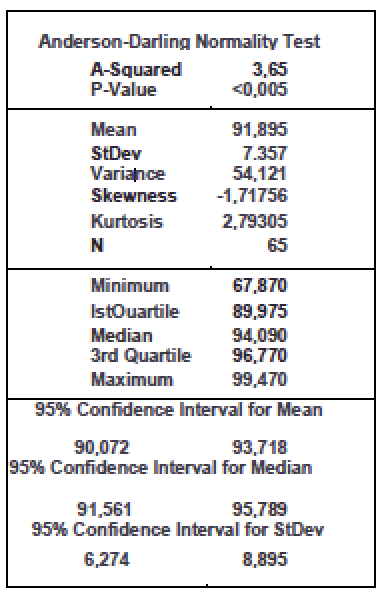

BFE Performance

- Synergex™ One has been externally tested 65 times for BFE performance

- Median BFE result >94%

- 95% of results have been over >90% BFE

They continue to test and improve our process to decrease the BFE variability

|

|

|

Face Mask Media

Converting of our media

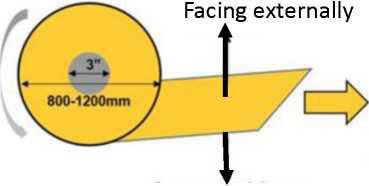

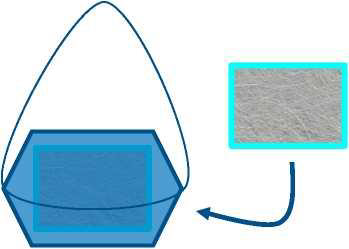

Splash Resistance

- Synergex™ One passes EN 14683 test for splash resistance.

- To achieve this the product must be converted in the correct way the fabric facing the inside of the roll must be the outside face of the mask - See diagram.

Converting

- Synergex™ One has been converted with and without nose wire.

- It has been converted with a fold at the top and bottom, and without.

- It has been reported to run very smoothly on multiple converting lines.

- No additional layer is required to insert the nose wire from our experience with multiple converting lines.

Face Mask Construction

Increasing efficiency of textile masks

Disposable Face Masks |

|

|

|---|---|---|

|

|

|

Standard process is to laminate multiple layers together creating a pleated product. Traditionally would be a 3 layer: Spunbond / Meltblown / Spunbond |

Companies producing stitched products utilize our Synergex™ ONE single layer composite product and stitch into required form only requires addition of:

|

|

Testing & Claims

- Manufacturers of face masks are solely responsible to ensure their compliance with the EU [93/42] Medical Devices Directive, the EU [2017/745] Medical Devices Regulation (MDR), the Regulation EU [2016/425] on Personal Protective Equipment (PPE) and/or any other applicable regulations and relevant standards.

- The brand owner of the finished face mask is solely responsible for achieving this certification and selling under the correct filtration efficiency mark (BFE, FFP1 etc.)

- Converting and transforming of the face mask into a finished product can influence the final performance level achieved

- Mask producers should always test materials externally to ascertain the level of filtration efficiency provided, and to certify this performance - this does not guarantee the certification of the finished face mask

Accredited labs collaborated with:

|

|

To find out more about our face mask material, please give us a call at (203) 878-1379, fax us at (203) 876-0949 or email us at info@santeccorp.com